How to Choose Knife Steel

Share

A worker must first sharpen his tools if he wants to do his job well. A good knife is essential for chefs, hunters, hikers, campers and other outdoor sports enthusiasts to do well. But the products on the market are dazzling and the quality is uneven, causing everyone to be confused about how to choose the right tool.

We usually judge the pros and cons of a knife from three aspects: the overall design, forging process and materials. The overall design mainly depends on personal preference, whether its shape, structure, blade profile and edge grinding are what you like, and whether the design details are in line with your daily use habits. It is difficult for us to use a specific quantitative index to measure whether the forging process is advanced or not. In many cases, it needs to combine the characteristics of the material to obtain a delicate balance. The material of the blade determines whether the knife has an objective condition for excellent performance. An excellent and reasonable metal content configuration is very important to the quality of the knife. The specific composition of the steel is quantifiable. It is simple and intuitive to judge the performance of the tool by studying the composition of the steel.

The common knives in the market are high-carbon steel, high-carbon manganese steel, stainless steel, high-carbon stainless steel, ceramic, and titanium alloy. Here is a brief introduction to their respective advantages and disadvantages:

- High carbon steel: carbon steel with carbon content ≥ 0.6%. The knives made with it are cheap, sharp and easy to grind, have good cutting ability, and are suitable for cutting hard objects such as bones. Its only disadvantage is that it is easy to rust and requires timely maintenance.

- High carbon manganese steel: Add a certain amount of manganese to high carbon steel to increase toughness and hardenability. Its performance characteristics are similar to that of high carbon steel, but its toughness is slightly stronger than that of high carbon steel.

- Stainless steel: refers to a type of steel with anti-corrosion characteristics, and its composition contains more than 12% chromium to achieve the anti-rust effect. The disadvantage is that the composition of stainless steel often reduces the carbon content and increases the chromium content to enhance rust resistance. This will cause the cutting edge of the tool to become soft and not sharp, or become hard and brittle, and difficult to sharpen. This has an obvious disadvantage in outdoor tools.

- High-carbon stainless steel: It is a kind of stainless steel, which refers to stainless steel with a carbon content of more than 0.7%. The corrosion resistance of stainless-steel decreases as the carbon content increases. Therefore, most stainless steels have low carbon content (0.1-0.4%), and the tool hardness is not high. Therefore, it is sometimes necessary to increase the hardness by increasing the carbon content. At the same time increase the content of chromium to balance corrosion resistance. Therefore, compared with stainless steel knives, high-carbon stainless steel knives are more expensive, have poorer corrosion resistance, but have better strength and hardness.

- Ceramic knife: made of zirconia powder sintered at high temperature. It has the advantages of high hardness, easy to clean, no rust, no metal residue when cutting food, thin and sharp, etc. The disadvantage is that it is brittle, cannot cut hard objects, and is easy to chip when the cutting edge falls.

- Titanium alloy knife: usually made of β titanium alloy, the advantages are sharpness, lightness, and excellent corrosion resistance. It is very suitable for diving knives. The biggest disadvantage is that it is expensive.

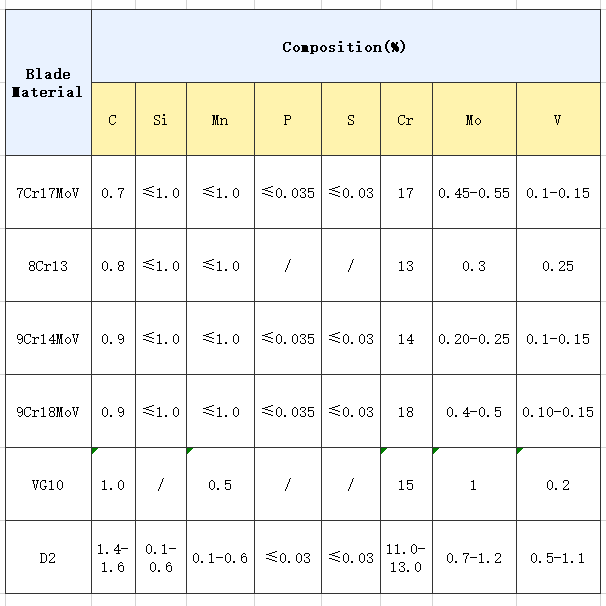

Comparing the characteristics of different materials, Masalong mainly produces, designs and sells high-carbon stainless steel outdoor knives. At present, only Kni218 is a limited-edition titanium alloy knife. The comparison chart of the chemical composition of different materials of Masalong knives is shown below.

We can roughly evaluate the hardness and rust resistance of the tool by the carbon content and chromium content. In most cases, toughness is complementary to hardness. Under high hardness, general wear resistance will increase and toughness will decrease. When choosing a tool, we need to make a reasonable combination of hardness, wear resistance, toughness and rust resistance, so that it can be used in a suitable environment.